Newman

- Home

- Brands

- Newman

Newman

Established in 1973 David Newman set out to create the only company in the country dedicated to manufacturing FDA compliant gaskets, “O”-rings and custom molded parts. He started with production of 1.5” and 2” clamp gaskets. In 1976 the first national distributor came aboard. Soon Newman had a national and international distributor network along with several OEM accounts.

Production expanded over the next few years to include the most popular, as well as hard-to-find gaskets, with expansion into other markets following. A new horizontal injection molder was added to the existing lineup of company equipment, and gave Newman nearly limitless production capabilities of quality, sanitary components.

Newman have a full line of the latest molding and lab equipment in-house to help in both production and quality control – equipment that gives us the kind of advanced expertise and technology that we pass on to you.

The equipment includes a 160-ton Vertical Injection press for EPDM and Viton™ gaskets and other parts. Newman also have a 60-ton Liquid Silicone Injection press for the production of flashless silicone gaskets and “O”-rings for the pharmaceutical industry.

Beyond the new equipment, Newman have upgraded and redesigned all of our compression, injection and Teflon® fluoropolymer tooling. The deflashing process is handled by a cryogenic deflashing unit or is finished by hand when necessary. In addition, every batch of polymer and every lot of gaskets is tested for physical properties and optically inspected to meet tolerances. Newman’s complete line of equipment and upgrades means we are even more precise and efficient in filling your orders.

Today, Newman continues to serve every element of the sanitary processing industries. Along with rubber-based compounds, Newman produces Teflon® fluoropolymer and Silicone components. State-of-the-art equipment in the form of a Liquid Silicone Injection Molder and Vertical Injection equipment are in place. A 22,500 sq. ft. production building expansion was completed and now all production, shipping and storage is under one roof for maximum efficiency.

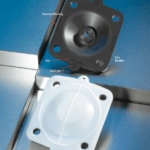

NEWMAN - NEWFLO DIAPHRAGMS

Precision fit and designed for ITT®, Saunders® and GemüTM valves, Newman NewFloTM diaphragms deliver exceptional performance in today’s demanding pharmaceutical processing environment. As always, you can count on Newman’s reputation for excellence, success and expertise in the pharmaceutical industry.

Dyneon™, TFM™ and Hostaflon® are trademarks of Dyneon a 3-M company. Time-Tested Materials, Third Party Verified Performance.

- The elastomer backing is manufactured from Newman’s famous polymer-rich 2107 EPDM compound.

- The TFMTM facing of the diaphragm is made from time proven modified fluoropolymer, the choice of the diaphragm valve industry for pharmaceutical applications and validated for years. Manufacturer certified USP Class VI.

- Mechanical testing by third party industry experts to 500 steam cycles and over 100,000 valve cycles has demonstrated exceptional steam resistance and long term durability.

Newman’s backings are shown to impart outstanding sealing properties at the lowest bonnet torque values. Certified Peace of Mind and Ground Breaking Traceability.

- Each diaphragm meets the requirements of FDA CFR Title 21 177.2600 (elastomers) and paragraph 177.1550 (perfluorocarbons) and USP Class VI.

- Setting a new standard for traceability and causing a stir across the industry, every diaphragm is fully batch traceable at the part level, an exclusive in the industry (patent pending). This means that you will know the exact style, size, composition and provenance of every diaphragm in your system, simply by looking at the back of the diaphragm.

- Each diaphragm is backed by Newman’s unbeatable 35 year history in manufacturing of premium elastomer parts for the pharmaceutical industry.