Services

- Home

- Services

Projects Completed

Dedicated Customer Teams & Industrial Services

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

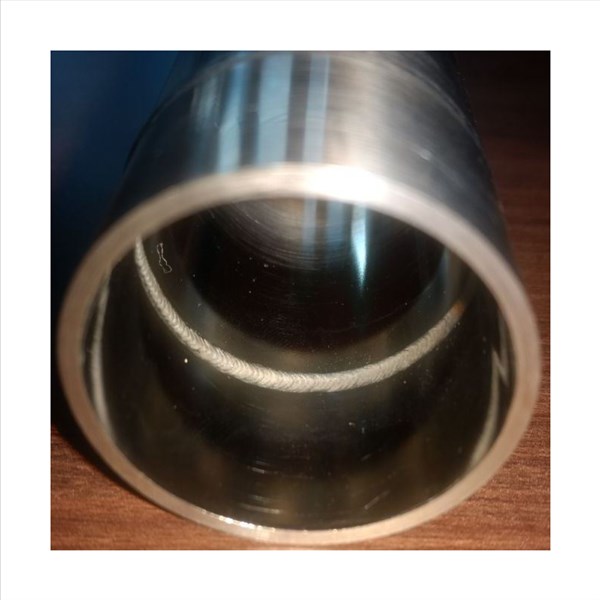

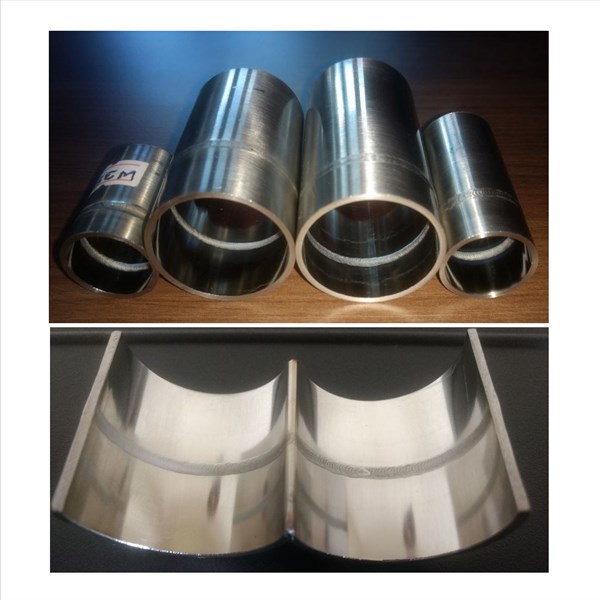

Weld Sample

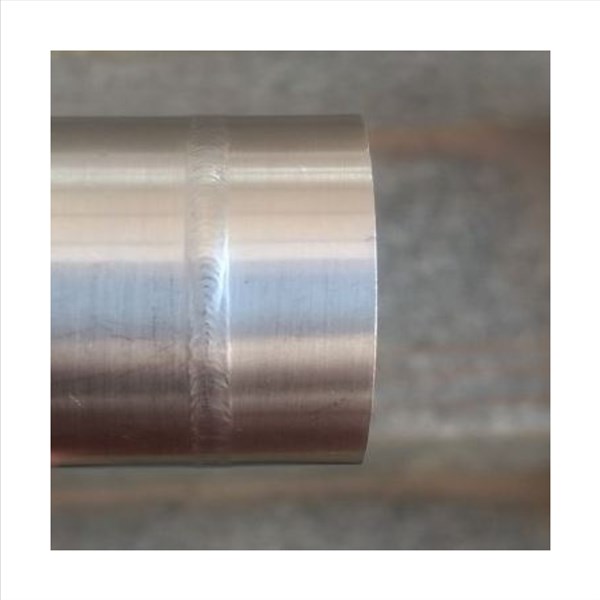

Cleanroom Piping